Working all day surrounded by mountains of records sounds like a career goal worth pursuing. James Knight at the British Library Sound Archive does just that. Groovy Times grills him about his enviable day job and discovers why PVC sleeves are the great satan

In autumn 2023, London sound archivist and DJ James Knight got vinyl fans all hot and bothered with a social media shoutout for someone to assist him in his day job at the British Library Sound Archive removing “bastard thick PVC sleeves” from some of the collection’s many LPs. Unsurprisingly, the idea of hanging out in one of the largest collections of sound recordings in the world was met by a chorus of oohing, ahhing and “when can I start?”. It also got us wondering: what even is this archive he speaks of?

James started his own vinyl journey buying electronic music in the mid-90s, eventually playing his records out (on NTS Radio and in clubs) as Low Bias and exploring the world of sound archiving. After a stint working for Vice, James wormed his way into the British Library Sound Archive (previously the British Institute of Recorded Sound and National Sound Archive), where the shelves creak under the weight of recordings deposited by labels and collectors (AKA published material) and a more sprawling, esoteric collection of unpublished material.

In his role as a preservation coordinator, James focuses on the latter: “Material that has never been commercially released or manufactured” and which spans classical, radio, oral history, wildlife and mechanical, language and dialect, drama and literature, and world and traditional music. James’s job, he explains, is to look at new collections in situ, check their condition, organise shelf space, collect data and schedule digitisation. Suitably impressed, we called him to chat about this record nirvana and to get some tips on record care and preservation.

We’re fairly format agnostic. If a label releases something on CD, vinyl and cassette, we’ll take all three of those plus the digital file. The format is unique and an artefact in itself that is worth acquiring. There may be liner notes. There could be things unique to the vinyl pressing not available on the cassette or the CD, and vice versa. There could be a load of stuff in the cassette release not in any of the others. So we take in all things. We’re not making subjective calls about whether this is good or bad music, or whether it fits into any kind of genre – that’s not the point. The point is to have a large collection that is representative, so that in decades’ or centuries’ time, people can look back at it. We’re a research facility.

We have a risk matrix that takes into account the scarcity of the recording. If it’s unique, it’s a higher priority collection than something that is rare or common. We take the scarcity value into account and then we take into account the potential technical obsolescence of both the format and playback equipment. A good example of this is open reel magnetic tape. Open reel tapes were a commercially available format for decades, whereas minidisc and DAT machines were really only commercially available for a few years and were not mass-produced formats. So when you’re looking at formats and how risky they are in terms of preservation, it’s not necessarily the older formats that are at higher risk. Some of the more modern formats are higher risk, because of technical obsolescence of the playback machines.

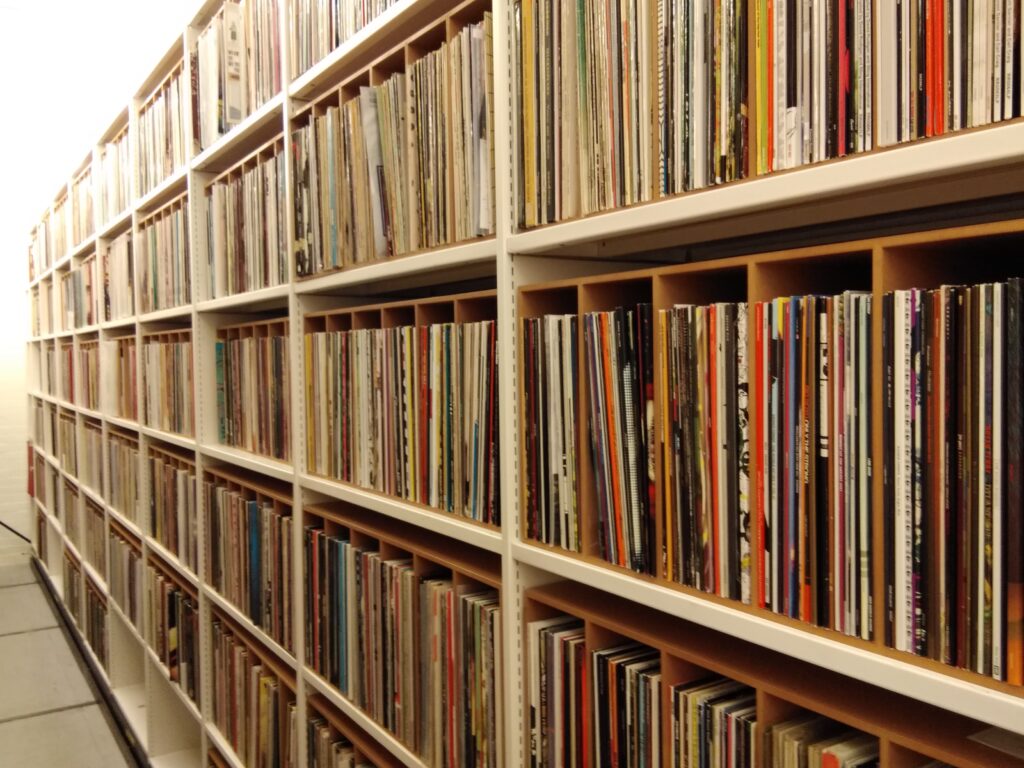

We split up and organise the collection by format. There are one and two LP sequences, one and two 12-inch sequences, one and two seven-inch sequences, and one and two test pressing sequences. That covers a litany of sins: promo, white label, test pressing, dubplate. We hold two copies of everything, which means there are at least seven sequences of vinyl. Then we’ve got multiple shellac sequences, multiple lacquer sequences. I would say, with vinyl, we have not far off a million discs. The main one LP sequence is above 300,000 now. The two LP sequence is about 200,000. And then you’re talking about hundreds of thousands in the other sequences. Much to my chagrin, though, there’s no 10-inch sequence.

We take any copies of a record that are not the same pressing. So if you were to look for, like, Rumours or the first Jefferson Airplane album, we’ll have lots of versions of those. That’s what differentiates us from a domestic collector. We’ll take multiple copies that are ‘unique’. It will go as far as different matrix numbers; even if something has the same ‘catalogue number’, we’ll check the matrix numbers to see if it’s a different pressing. So there’s a lot of ‘duplication’, but we would argue that, from a collection perspective, those are unique artefacts.

We hold somewhere approaching half a million shellac discs. And again, there’s massive ‘duplication’ within that because a lot of shellac was pressed in shorter runs or in ‘unique’ pressings. So there’s a lot of matrix runout groove differentiation between the ‘same’ records. Probably more so than with vinyl. Vinyl’s mass duplication process meant the stampers were more robust. You can stamp way more records with the same mother and father stamper in the vinyl process than the shellac process. We do still get elderly gentlemen – and it is almost always men – that come in and call up the physical artefacts. There are huge printed discographical books about early 20th-century shellac labels but even to this day people come in checking our matrix numbers to make sure there’s not something they’ve missed. It’s a niche pursuit but someone’s gotta do it.

PVC sleeves are the great satan. People have mugged themselves off spending a fortune putting records in things that are destroying them. The ‘c’ in PVC is chloride and the chloride reacts to the sleeve. You’ve almost certainly seen this if you’ve bought old records in PVC. The outers, or the jacket, will become wavy. The chloride does that to the sleeve and will sometimes stick to it, but the thing that’s more problematic is – and you see this with picture discs that are stored directly in PVC – it causes misting that degrades playback. It’s not going to make your record completely unlistenable but you do notice a drop-off in sound quality. They’ll begin to smell, too.

Get the cheapest sleeves. You know, the ones you can get 100 for a tenner; they’re way better. They’re polyethylene and there’s no chloride in them. So they’re inert compared to PVC sleeves.

The biggest thing you can do is probably the trickiest but there are loads of videos now on YouTube explaining it. It’s having your cartridge and stylus correctly weighted and aligned. If your stylus, cartridge and tonearm weight are incorrect, then you’re damaging the grooves of the records. That’s the single biggest thing, making sure your turntable is set up correctly. You can spend a couple of hundred quid on a turntable or buy a really expensive one, but if you don’t set it up properly you’re just going to fuck up your records.

Lighter fluid really does work to clean off sticker residue. That’s why there’s always loads of lighter fluid behind the counter in the Music and Video Exchange. They’re cleaning off the last person’s sticker so they can put their sticker residue on it.

We use two fairly expensive machines for cleaning. One is made by an eccentric English inventor called Dr Keith Monks. If you ever go into Reckless, in Soho, they have one behind the counter. The Monks machine is what is called a threaded cleaning machine. It’s a tonearm with a piece of thread. You drop the tonearm on the disc and the thread passes through the grooves, constantly moving through the tonearm while the record moves, disturbing the grit in the grooves. Then there’s a wet tonearm that pours fluid, and a little hoover sucking everything up.

We also use a sonic bath. It’s an ultrasonic bath you drop the record into, then rotate the record slowly around. There are ultrasonic particles that greatly disturb all the crap in the grooves. What we’ll usually do for a disc is a Monks clean, an ultrasonic clean, then a second Monks clean. It’ll usually be pretty clean then.

Monks do make a consumer version of their machine and there are multiple domestic ultrasonic machines on the market. We have quite an industrial one that’s usually used for cleaning hospital implements. We can drop in 10 discs and rotate them simultaneously. The new machines commonly look like toasters. You drop one record in and it slowly moves the record around. They’re really cool, but they do cost a grand or two. There’s also a cleaner by Discwasher, which is more like £50-£100. For those, you make a little bath of record cleaning fluid and inside are four goat hair brushes. You use a hand crank to rotate them. I recommend them if you want to go to the next level above cloth, fluid, brush.

It’s good to have records stored inside the jacket in poly-lined paper sleeves. A poly-lined sleeve is superior to regular paper ones. I have all my records in poly-lined sleeves and I’ll clean a record every time I play it. Part of that has to do with the cleaning we do at work and seeing what comes out of records, like you wouldn’t believe – especially secondhand records.