A brand new pressing plant has opened in Scotland. Groovy Times chats down to co-owner David Harvey about his pressing concerns

Ever dreamed of opening a record-pressing plant? How difficult could that be? One man who knows is David Harvey, co-owner of Seabass Vinyl, a new company based in East Lothian. Seabass is Scotland’s only pressing plant, and the company says it aims to support the country’s music business by offering short runs, fair prices and high quality. Groovy Times caught up with Harvey down the line from Nashville where, on a fact-finding mission, he was sitting in on the pressing of Dolly Parton’s Rockstar album at The VinyLab.

How did the business get started?

My partner, Dominique, and I moved to Scotland in 2019. We had both been working as management consultants but always had the idea to set up a physical business together. We wanted the opportunity to create some employment in Scotland – for ourselves and for other people.

We were aware there was a backlog of artists looking to press records, but frankly didn’t realise the machines were available to buy and being manufactured again these days, which we learnt in a Tweet from Simon Raymonde of Cocteau Twins. This whole mad investment that we’ve made, this whole journey, it’s probably his fault to be frank!

What steps followed from that initial crazy idea?

In November 2021, we went to see Dublin Vinyl, to see the actual mechanics of how it was going to work. In March 2022, we put in an order with manufacturers Pheenix Apha AB. They’re based in Sweden, so quite close to us. We’ve got a great relationship with the company, and their CEO and co-founder, Niklas Poblens.

How did you finance buying the presses?

We were in the fortunate position of being able to finance 90% of the business ourselves. We’ve set up two businesses, including a commercial property business to build our premises. In reality, it’s not far off a £3m investment.

Are your life savings in this?

Yeah, we’re all in! It’s terrifying! More seriously, we ended up six or nine months behind where we wanted to be. We wanted to be pressing records by March 2023. In addition, buying records is very much a discretionary spend. The industry has become much more competitive.

But we’re not doing this for world domination. We want to be able to charge fair prices to artists. We’re probably in a better position because we don’t have investors. We don’t have any pressure on us from that perspective.

We have to have orders and we have to be able to make a profit on those orders, but we also have to make good records. That’s the key thing for us really and that’s the unknown for all of our customers. But we’ve done the value proposition, we’ve done the business case and we think there’s a demand for a good pressing plant in Scotland. There’s been a tremendous amount of support from the industry in Scotland, that’s been quite heartwarming.

You’ve been doing the research. What do the rest of us not know about record pressing?

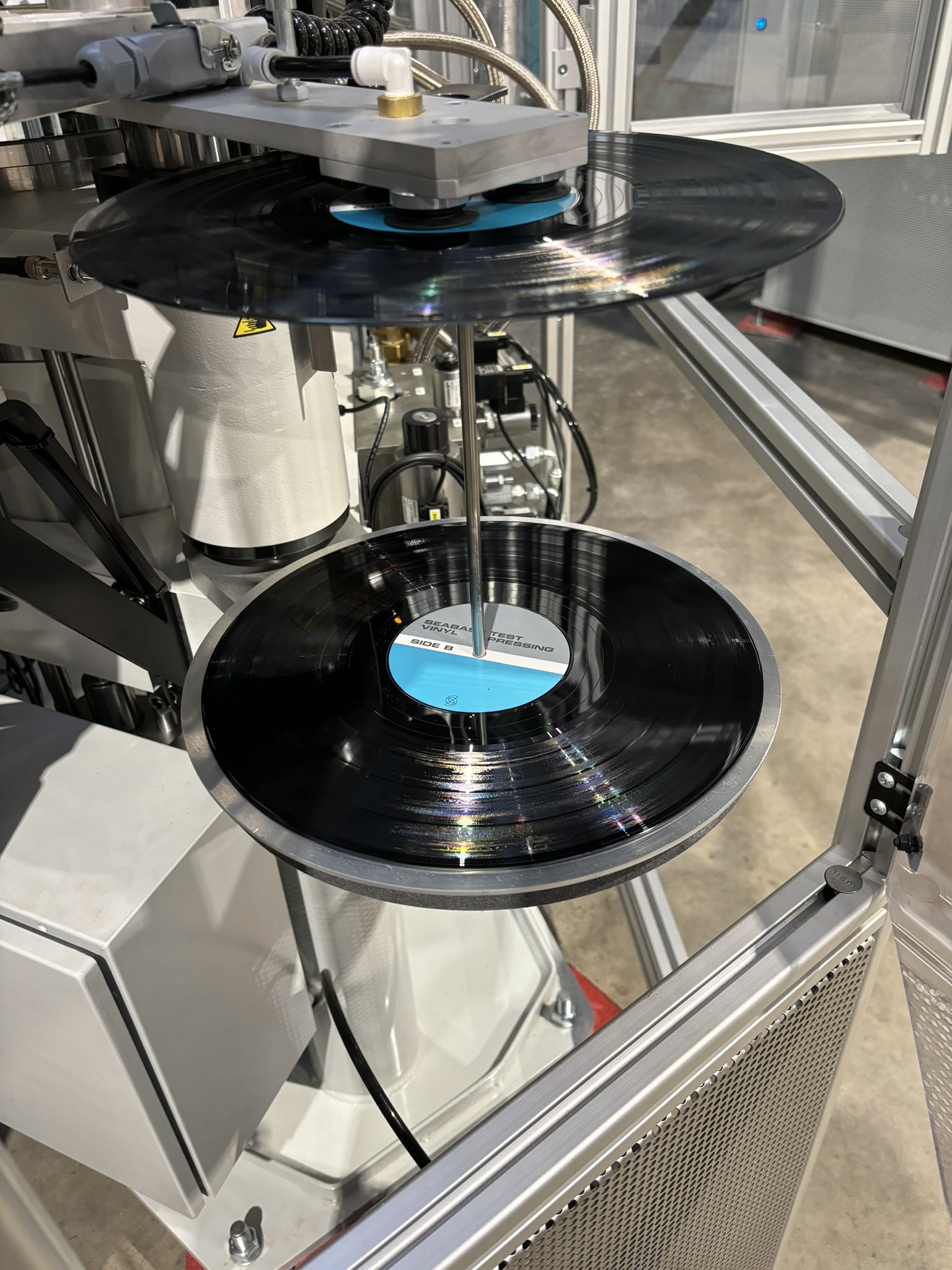

I think the record press itself was only about 25-30% of the investment. But the actual infrastructure that surrounds the press is very complex. Then there’s quality control. You probably spend 20-30% of your time setting up the machine to press one record. And you check that one record. And then once that one record is working, then you can print 8,000 Dolly Parton records. There’s an investment in time to get things going. The complexity of the machines is quite high and the number of things that can go wrong day-to-day is quite high too.

Overall, it’s a technically complex process to press a record at the right quality, and to have a consistency of performance of the presses. It’s definitely a lot more of a craft than it is an industry or a manufacturing business. We have a separate team that’s going to inspect the records visually. If they see something that looks suspicious in terms of a pattern on the record that isn’t quite right, they will listen to it again to check and to confirm if there’s an issue. You can see anything up to 10% of your production falling out in that quality assurance phase. At The VinyLab, in addition to a visual inspection of every record, they also listen regularly to records direct off the press during the production and as part of the final quality assurance process if there is a potential issue.

We hear a lot about lead times and delays at pressing plants. What’s the current situation?

Most pressing plants were quoting six to 12 months lead time, but there is significant additional capacity now and lead times are around 12 weeks. For now, our estimated lead time is eight weeks during our launch phase, from the moment the order is placed, and when artwork and mastered audio files are received. That lead time may change when we work at capacity later on.

You’re a music fan who loves hi-fi. What would be your dream pressing job?

The dream for me would be something by Blue Nile. I listened to their records over and over again when I was a teenager. I think the other one that would be of significance to us is Belle And Sebastian. Our son is called Sebastian and his nickname is ‘Seabass’, which is why we’re called Seabass Vinyl.